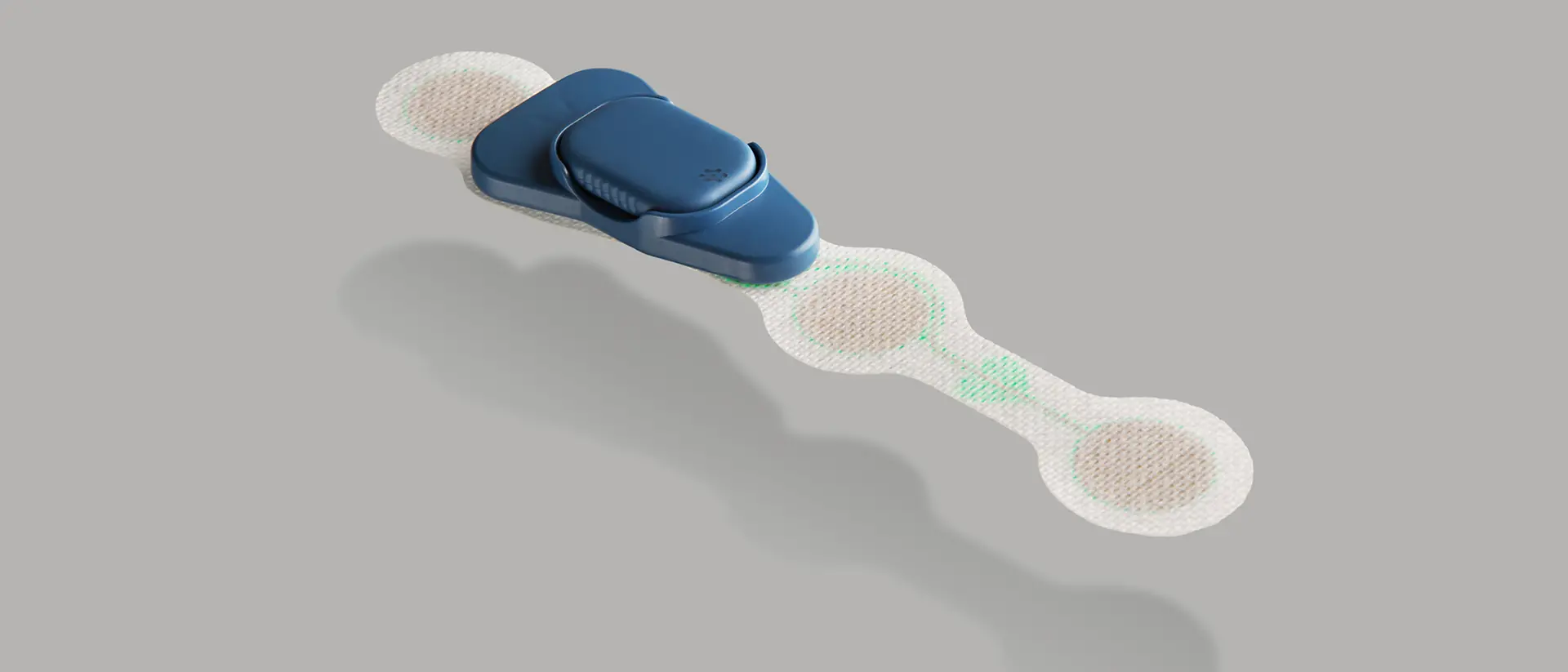

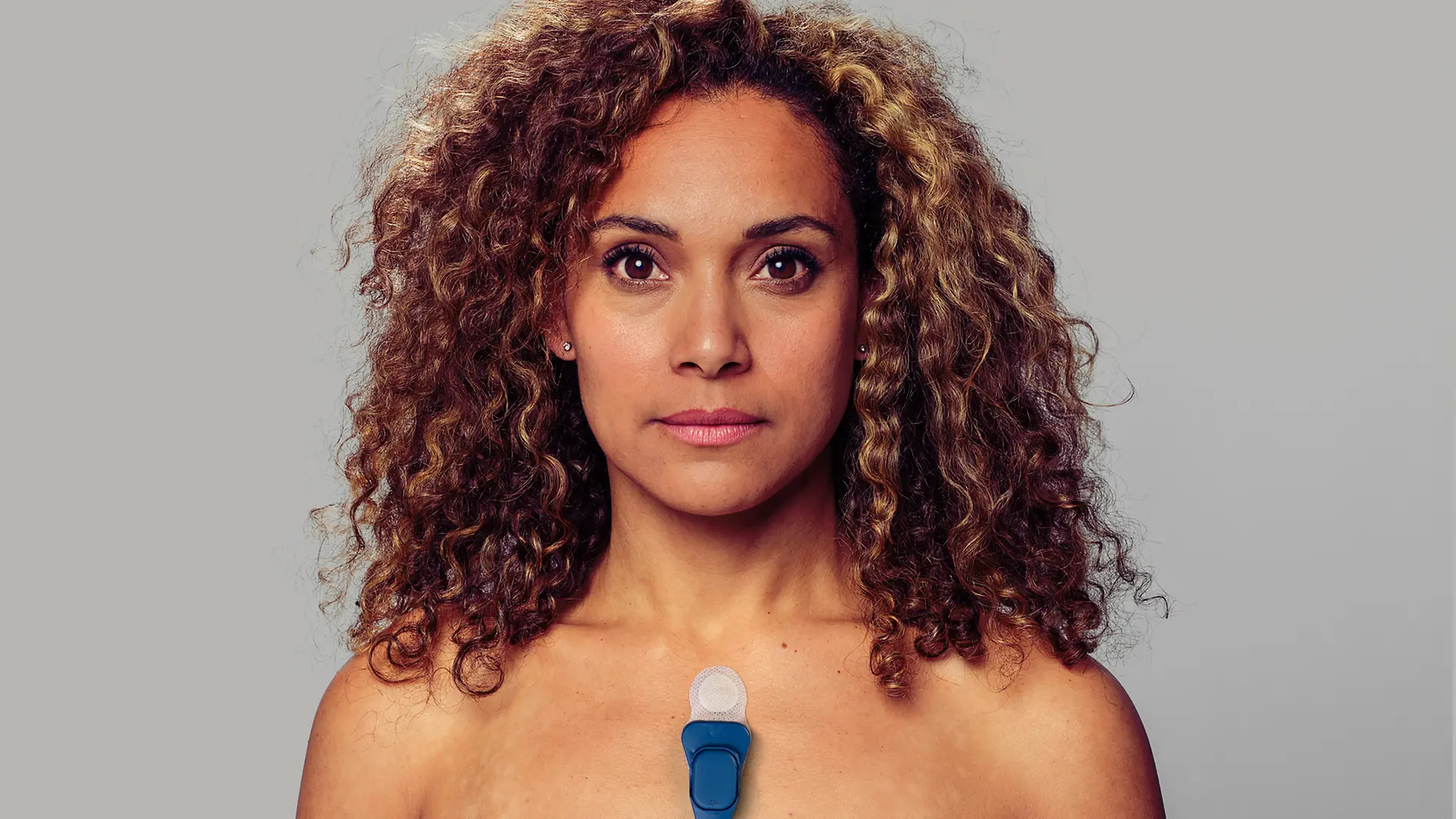

The market of smart, body-worn medical and hygiene solutions is transforming. Today’s players range from big established medical equipment manufacturers to big tech giants such as Apple, and technology startups with unique ideas disrupting the market landscape. Together they are creating an environment with new market dynamics, much the way Amazon or Google did in the early 21st century. Their goal is to enhance both the form and function of body-worn products, while collecting meaningful patient data – from heart rate, blood pressure and moisture or glucose levels, to oxygen saturation – and interpreting them with the help of artificial intelligence (AI) to improve patient health and treatment.

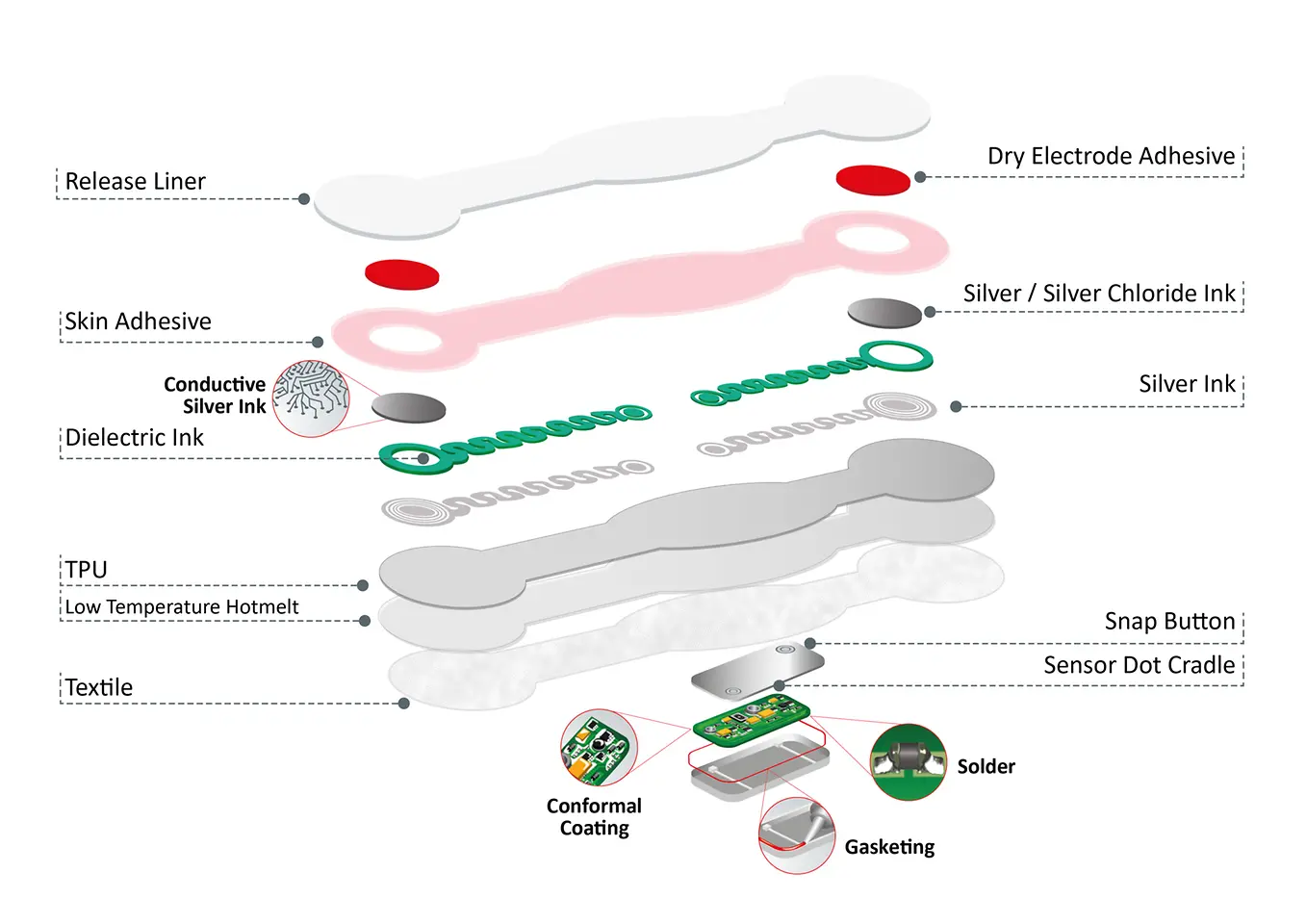

Henkel's Adhesive Technologies business supports this transforming market by providing these companies with both material solutions and the ecosystem partners they need. In addition to a full range of medical adhesives, our specialized conductive inks and coatings enable the addition of thin, lightweight circuitry. These flexible printed circuits revolutionize how electronics can be designed into medical wearables. By combining our material expertise and ecosystem of industry partners, we enable our customers to innovate their products without having the hassle of innovating.

Our credentials: material experience in adhesives and functional coatings for the medical industry, expertise in printed electronics, and a global track record of providing high-quality solutions. And we offer our customers peace of mind: our materials are certified and meet the standards of the medical industry.

Given the cost and resource pressure in the global healthcare markets, it is becoming increasingly important to collaborate with decision-makers along the value chain and to embrace transformative digital innovations as an ecosystem. Our collaborations with technology start-ups, manufacturers of hygiene or medical solutions, and long-term-care facilities or hospitals were created to smooth this path. It acts as a link between our customers – the producers of medical & hygiene wearables – and hospitals or long term-care facilities. Together we pilot, test, and build solutions for new use cases enabling remote monitoring technologies. We support and conduct clinical studies to showcase the benefits smart wearables offer: cost, treatment efficiency, workflow, and comfort for both healthcare staff and patients. In this way, we generate a new market for our customers, attract new healthcare suppliers to the concept, and promote digitalization.