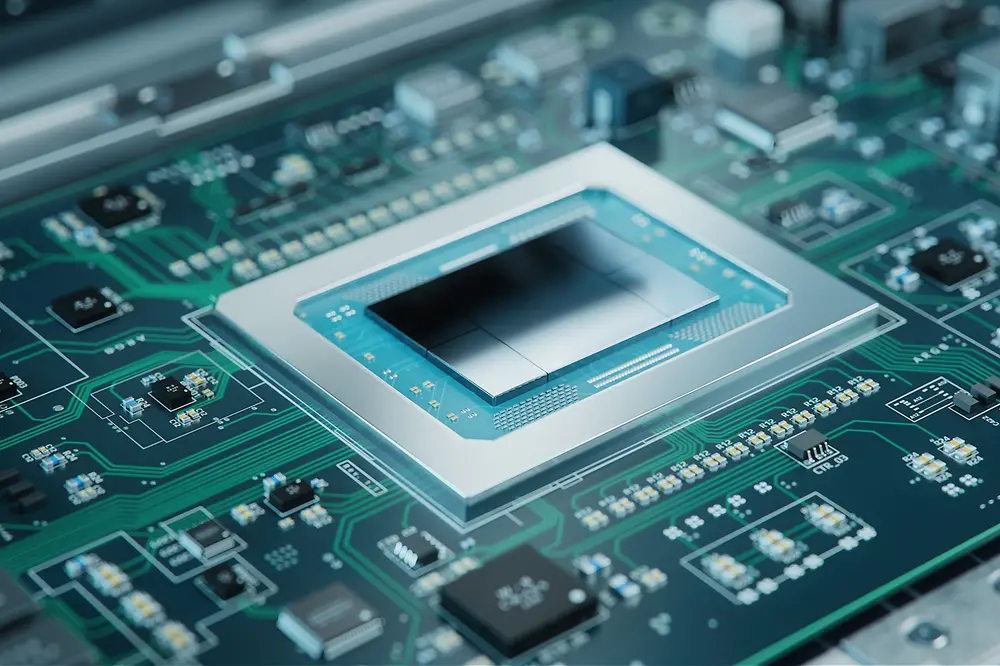

We accelerate battery innovation with a full set of development, testing, and validation services in one place. Our customers benefit from faster time-to-market through our in-house material application, advanced simulation, and full-scale testing. As an end-to-end solution provider, we support every stage from material selection to battery system validation. With a focus on performance, safety, and sustainability, our experts work closely with OEMs and battery manufacturers to deliver customized solutions that meet today's technical and regulatory requirements. The Center also offers full-scale battery testing, including temperature, humidity, leakage, and aging validation, with a TISAX-certified environment, advanced modeling and simulation tools, and automated dispensing at serial production scale. Our debondable adhesives empower battery circularity and recyclability and with the Path.Era digital battery passport we support traceability and transparency throughout the battery value chain.