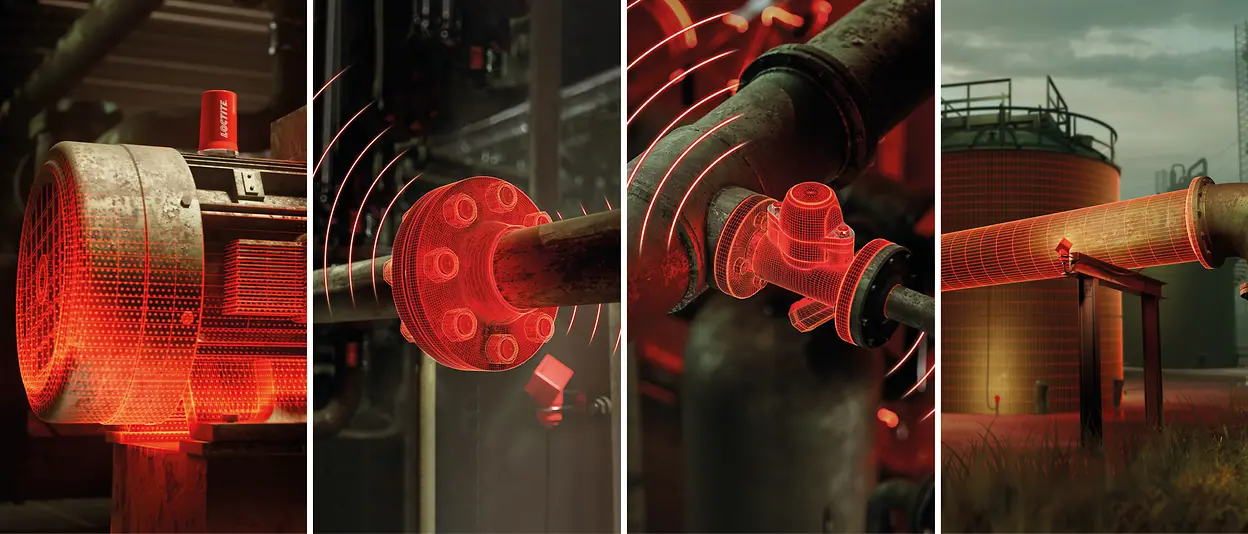

Companies across industries worldwide trust LOCTITE’s leading products for Maintenance, Repair and Overhaul (MRO). These adhesives, threadlockers, sealants, coatings and cleaners prevent mechanical failure, eliminate leaks and extend equipment life. It’s a portfolio featuring solutions for rotating equipment like pumps, gearboxes, turbines and conveyor systems. It also offers innovations for static equipment like pipes, storage tanks and heat exchangers. Customers rely on these products to keep their business moving – whether they operate a factory, mine, quarry, oil and gas refinery, power plant or water treatment facility. On top of these trusted technologies, LOCTITE Pulse now empowers industrial companies to explore ways of taking their MRO approach to the next level.

LOCTITE Pulse’s innovations have been honored with the “Engineering product of the year” award by the Digital Engineering Association as well as the “Best Smart IoT 4.0 solution award” by IoT Solutions World Congress in 2024.

What is this award-winning, connected solution? Find out here: