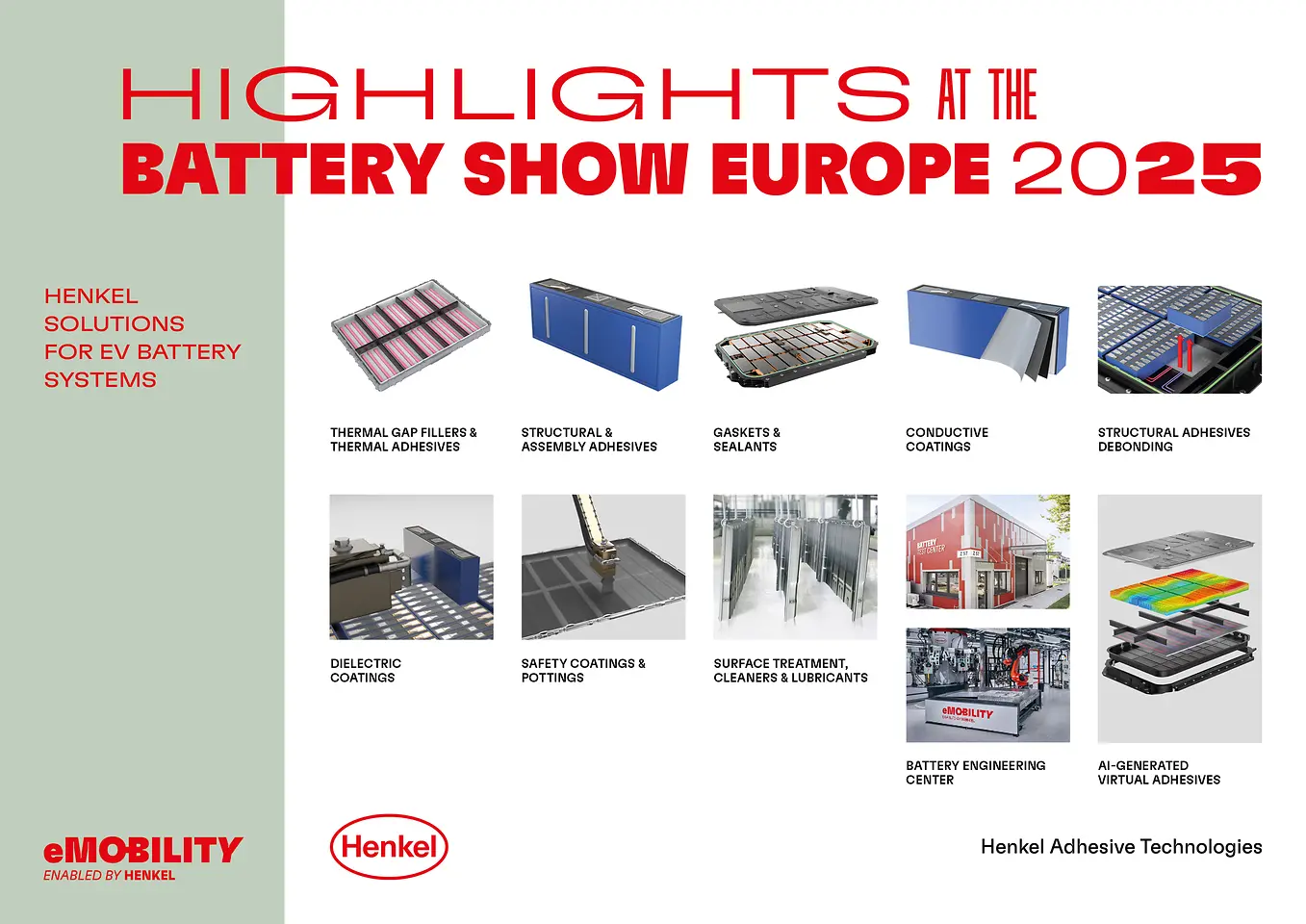

At ‘The Battery Show Europe’ (June 3-5, 2025, Messe Stuttgart, hall 10 – booth G10) Henkel will showcase its latest advances in adhesives, functional coatings, thermal management, and sealing solutions – key enablers of safer, more efficient, and more sustainable EV batteries. These core technologies, now enhanced with AI-powered simulation and debonding innovations, help OEMs and battery manufacturers reduce development cycles and costs, enhance performance and enable circularity across the battery lifecycle.

“At Henkel, we are collaborating closely with industry partners to push the boundaries of EV battery innovation,” said Frank Kerstan, Head of E-Mobility Europe at Henkel. “This year, we are excited to present cutting-edge capabilities – from virtual adhesives to breakthrough debonding and digital traceability of the battery value chain – all aimed at making battery systems faster to develop, safer to use, and easier to recycle.”

Shortening development cycles with AI-generated Henkel virtual adhesives

Henkel’s latest modeling and simulation capabilities enable faster, smarter EV battery development while reducing costs. By using AI to create virtual adhesives and digital twins, customers can accurately predict material behavior early in the design process, allowing for faster, data-driven decisions and reducing the number of physical prototypes.

Boosting battery performance with Henkel conductive coatings

To optimize battery cell manufacturing, Henkel will showcase its battery conductive coatings, which improve adhesion and conductivity in both dry and wet electrode processes. These coatings enhance efficiency, cost-effectiveness and sustainability in battery cell manufacturing, and play a vital role in boosting overall battery performance.

Replacing Mica sheets with advanced, automated Henkel safety coatings

Henkel’s safety coatings offer a reliable, scalable alternative to conventional Mica sheets, delivering superior thermal stability up to 1400 °C and electrical protection for improved passenger safety. Designed for automated application, Henkel`s coatings ensure consistent quality, reduce production complexity, and support easier end-of-life recycling – enabling more sustainable battery manufacturing. Additional safety materials, such as pottings, complete Henkel’s comprehensive safety portfolio for EV battery systems.

Henkel debonding of structural adhesives in liquid, film and tape format

Henkel’s breakthrough debonding technologies simplify battery disassembly and repair – including structural bonds up to 12 MPa – supporting end-of-line and in service repairs, second-life applications and end-of-life recycling. Live debonding demonstrations will take place hourly at the Henkel booth.

Henkel will also unveil Path.Era, a scalable ecosystem for digital battery passports, based on Catena-X. Co-founded by Henkel alongside leading industry partners, Path.Era is built to enable full traceability and circularity across the battery value chain.

Keon Lee, Senior Manager Product Development Battery Solutions at Henkel, will speak at the conference (June 3, 2025, 3:00 – 3:30 pm) on “Scientific advancements in debonding technology: Enabling repair and recycling of bonded components in sustainable battery systems.”

Explore Henkel`s full EV battery portfolio

A dedicated product wall at Henkel`s booth will feature a comprehensive selection of advanced materials for EV battery systems, including:

- Thermal Gap Fillers & Thermal Adhesives

- Structural & Assembly Adhesives

- Gasketing & Sealants

- Battery Conductive Coatings

- Dielectric Coatings

- Safety Coatings & Pottings

- Battery Repair Solutions

- Surface Treatment, Cleaners & Lubricants

Henkel invites visitors to discover how advanced materials and digital capabilities are reshaping the future of E-Mobility – with speed, safety, and sustainability at the core.