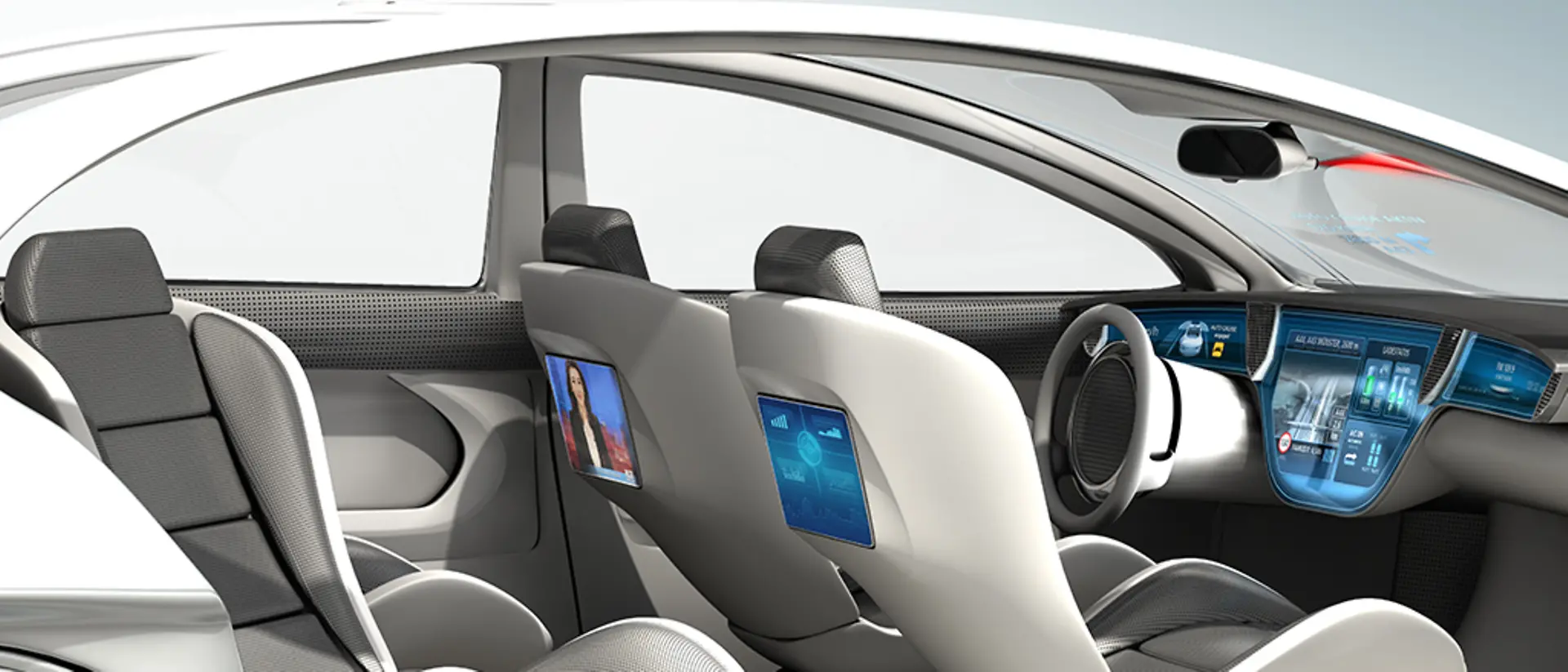

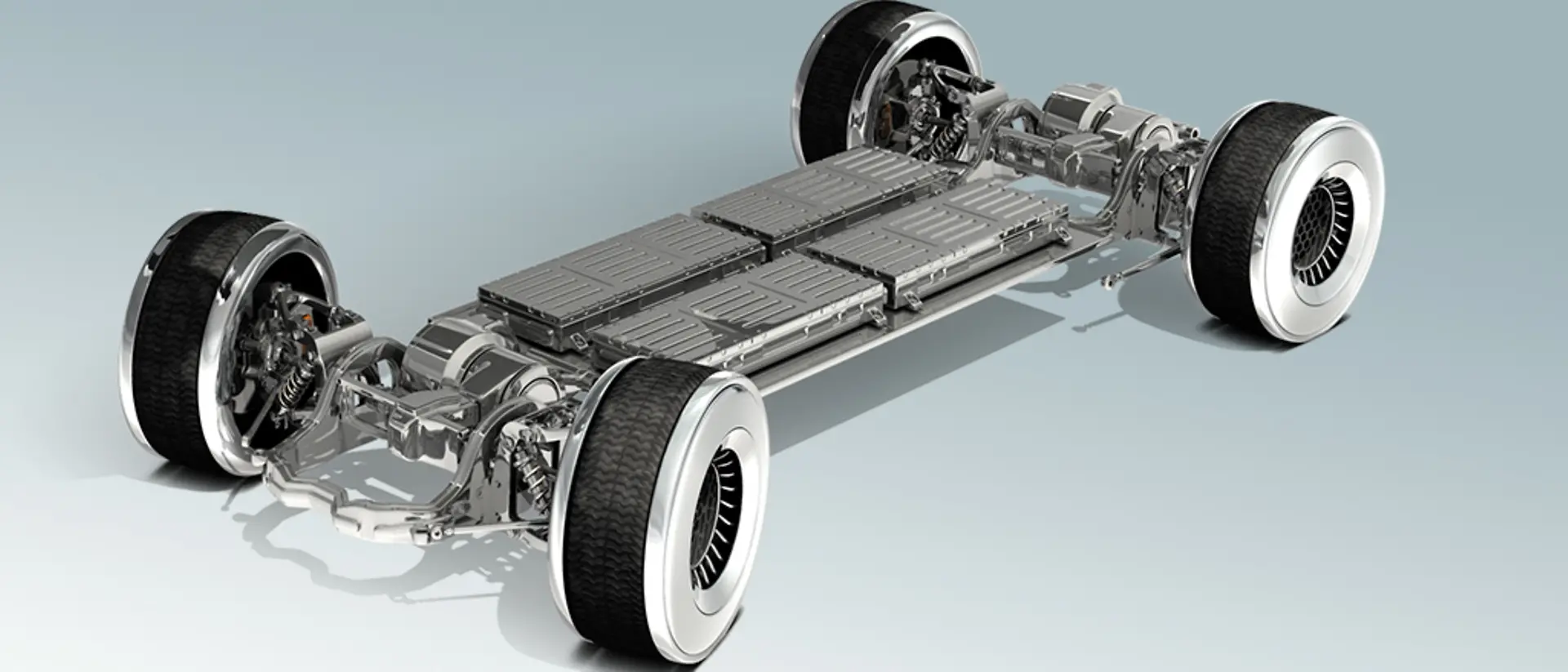

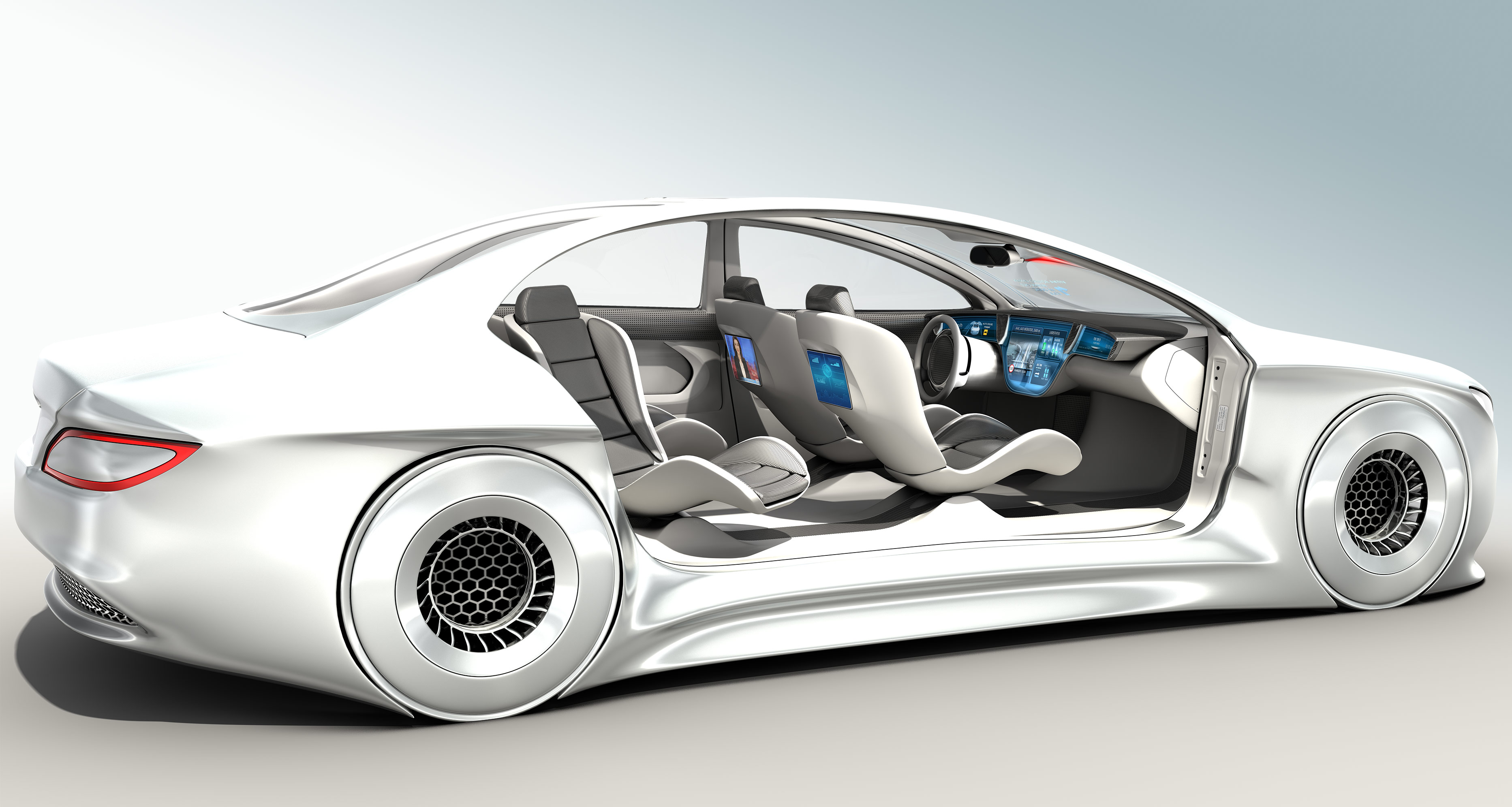

For years, car manufacturers have been struggling with the increasing weight of vehicles, because stricter requirements regarding active and passive safety, the multitude of electronic devices and components, and the batteries in electric cars all have a tendency to tip the scales. The heavier the vehicle, however, the greater its carbon emissions will be. That’s why the industry is turning to lightweight construction materials like aluminum or synthetic materials.

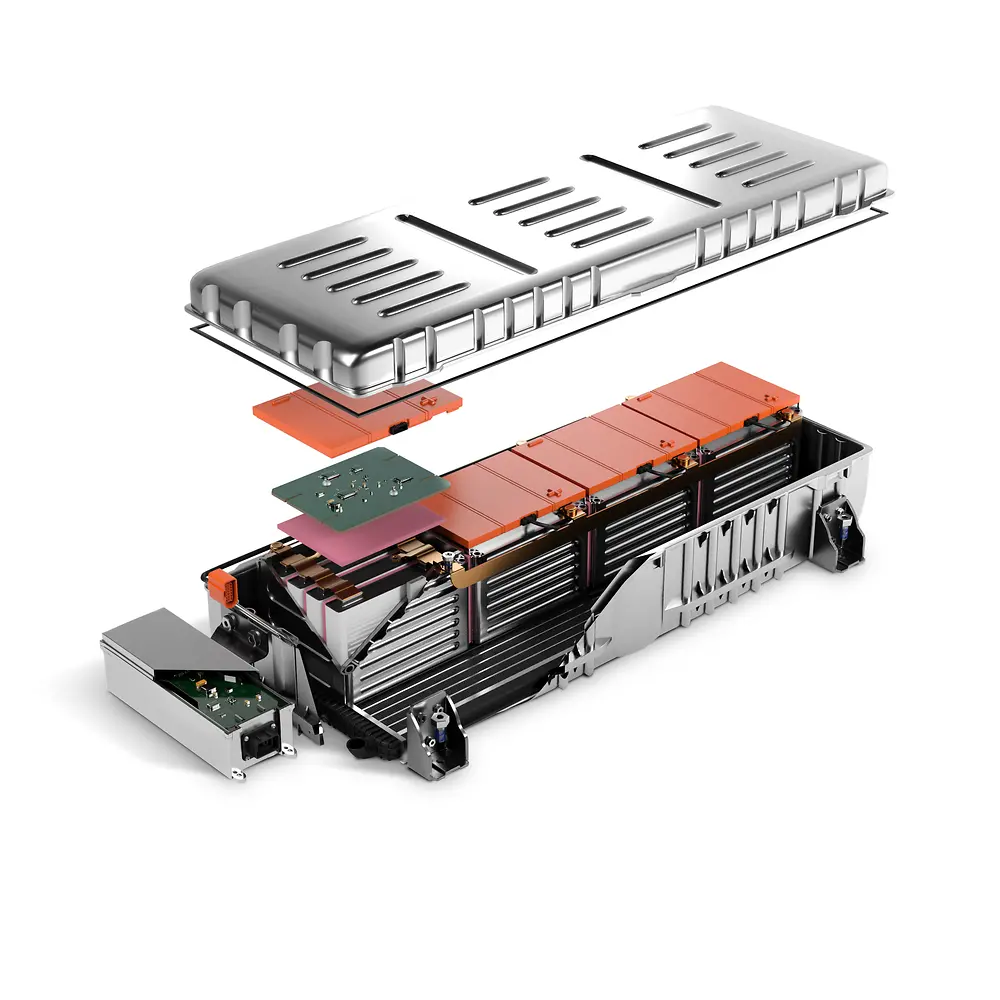

Henkel’s adhesives and sealants make lightweight automotive construction possible, because gluing is the new welding. It can reduce a car’s weight by up to 15 percent. Glued joints can withstand high amounts of stress from oscillations, vibrations and temperature fluctuations, and ensure that different materials remain securely and durably joined together. Among other things, Henkel adhesives are used on car body parts, engines, powertrains, gearboxes, rearview mirrors, seats and steeling wheels. At the same time, they also make cars safer, more resistant to corrosion and more enduring.