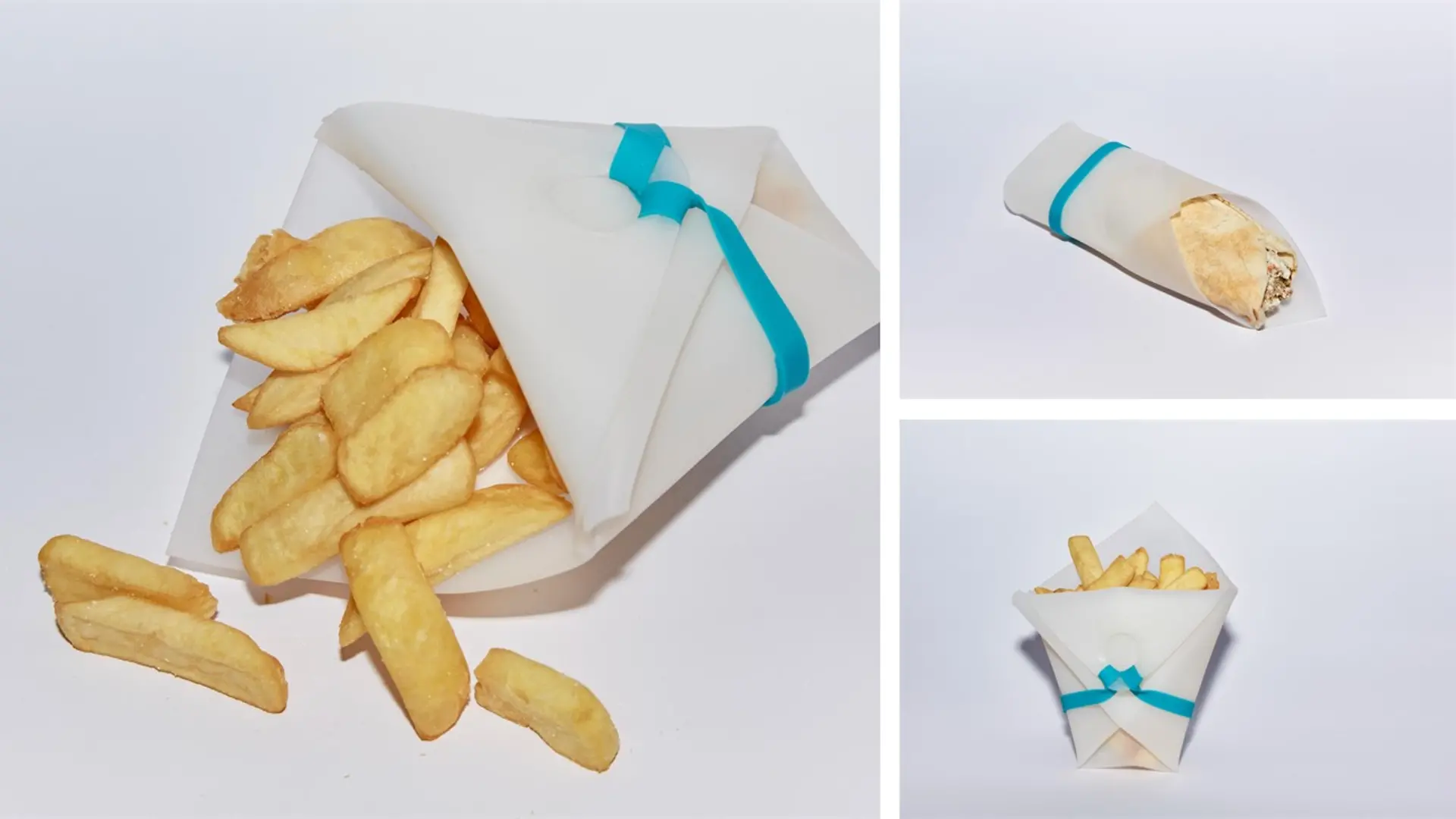

What does the ideal sustainable packaging look like? "No packaging at all" is what many would say. But is that the best solution for every product? Which truly sustainable and viable alternatives exist? We discuss these and many other questions in an interview with packaging expert Bernd Draser from the Cologne-based ecosign/Akademie für Gestaltung.

Bernd Draser: The answer is more complicated than you think. If a lack of packaging will not lead to a reduction in product quality, then we can confidently buy these products without packaging. As consumers, we can also send a message to retailers by avoiding buying products with excessive packaging. However, there are also a lot of products that are not suited to being sold without packaging as their durability, effectiveness and quality would suffer considerably. You then either have to use a lot more preservatives or have to account for a much higher level of waste, as would be the case with food – neither of which, in my view, is an acceptable alternative. In most cases, the ecological rucksack of discarded food is much more significant than the ecological rucksack of packaging. In this scenario, it makes sense to choose the lesser of the two evils. However, there is still plenty of potential to improve packaging.