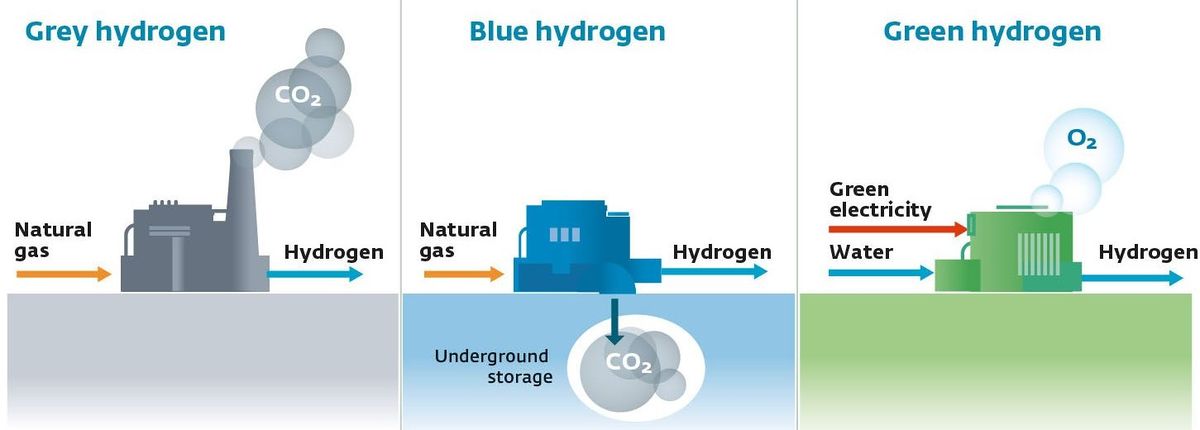

It sounds great – but some challenges are holding back green hydrogen. It is expensive to operate an electrolysis plant, for example, so there is a need to boost efficiency, ensure durability and cut process costs in these facilities. Furthermore, green hydrogen currently makes up around 0.1 percent of global hydrogen production3. Because it is still fairly uncommon, only a few fully certified solutions are available for hydrogen production, storage and transportation. However, green hydrogen is expected to become more common as the cost of renewable energy continues to fall and the push for net-zero gathers momentum.

Leaks are a major challenge for this sustainable feedstock. Hydrogen molecules are very small, which makes them difficult to trap or seal. The gas is also highly flammable, so leaks present a fire safety risk. Detecting leaks requires specialized technologies because hydrogen is odorless, colorless and tasteless. In addition, leaks contribute to climate change because hydrogen can react with methane and other greenhouse gases to extend their lifetime. And on top of all this, leaks make hydrogen production processes less cost-effective.

Solving these challenges is the key to scaling up green hydrogen and making it a truly viable alternative to fossil-based feedstocks.

Sealing up and locking down

Henkel is a leading provider of adhesives, sealants and functional coatings for a uniquely broad range of industries around the globe. Our researchers are actively adapting our technologies to solve the specific challenges for green hydrogen and accelerate growth for this sustainable feedstock.

Our products support efficient electrolysis processes, storage, transportation and use of green hydrogen. Examples include thread sealants, flange sealants and threadlockers from LOCTITE that stop leaks and prevent loosening of threaded connections along every step in the value chain – including electrolysis systems, valves, compressors, pumps, storage systems, fuel cells and other assets that are used in the green hydrogen economy. In addition, our engineers are adapting the successful LOCTITE Pulse smart maintenance technology to boost safety and cut costs by detecting and preventing hydrogen leaks.